Changes in physiological parameters and the apple stiffness due to the static and dynamic impacts

Author(s):

Abstract:

Background and objective:

Unlike engineering materials, apples are living tissues which survive after harvesting. Thus, post-harvest processes such as transporting and packaging should be carried out in a way that makes them less vulnerable. Among the agricultural products, fruits and vegetables are the commodities that due to their low resistance to the shell and high humidity, have a high sensitivity against mechanical damages that occur when processing them. In order to minimize waste, proper post-harvest management and convenient techniques for transport and storage are required. Mechanical damages can occur in three major ways, including pressure, impact, and abrasion. The pressure during the harvest may impose on the fruits by pickers or occur when fruits are stored in the bottom of the box. External damages may happen due to the weight of picked apples in the baskets in deep boxes or when transporting the boxes by hooks. In fruit packaging stations, pressure, impact, and vibration can occur when packaging of fruits in boxes, as well as the washing and waxing fruits. Pressure forces usually happen during transport and storage of the fruit. This study was undertaken to study the impact on sugar, phenol, acidity and fatigue area that play a major role in the final quality of the product.

Materials and methods:

Static and dynamic impacts and storage time were considered as the independent factors in this study and their effects were analyzed on the chemical parameters including sugar, phenol, acidity and fatigue area. The static impact was conducted by Instron Sntam with three loading speed 5, 7, and 10 mm/min for 1min. The dynamic impact was conducted by a pendulum that simulated the energy applied to apples that dropped. The amount of energy was equivalent to 2.25, 3 and 3.75 J. Apples that underwent impacts, were kept for 20, 40 and 60 days to measure the impact on changes of chemical parameters and determine the area of fatigue. After each storage period, the samples were photographed. The area of fatigue was measured using image processing techniques and Image J software. The image processing consists of two parts: hardware and software. The hardware of computers, cameras and imaging chamber is formed. The camera was connected by cable to a computer and the images were stored on a computer's permanent memory. Used computers used running windows seven, five-core central processing unit, and RAM was 4 Giga bytes. Computer is the processing of the data and the image acquisition step to the final step, the output data is the most important role. The used camera was a Canon, made in Japan, was mounted vertically inside the box. Shooting box was used just because all the photos must be taken in a constant condition of light regarding light intensity of surroundings and distance of apples from the camera. The Chamber was made of wood and shaped like a cube with dimensions of 45 × 45 × 45 cm, which is just an open area. Three eight-watt fluorescent lamps for lighting inside the box was fixed to the ceiling box around the triangle mounted camera. Image J analyzer is a powerful software with various uses. This software can calculate the area and pixel value statistics of user-selected portions of the image. Factorial experiments were carried out in a completely randomized design with three replications.

Results:

Results revealed that acidity changes and fatigue area during the storage under static and dynamic impacts were significant at 0.01 and 0.05% and for phenol and sugar were significant at 1 and 5%. Also, in this test, sugar content and acidity were generally reduced over time, and phenol and fatigue area increased.

Conclusion:

In order to avoid excessive reduction in sugar and fruit quality, maintenance time should be reduced as much as possible. Phenol increased during storage, after applying impact; its oxidation when contacting air results in toxic compounds that are harmful to humans. Therefore, packaging using the pads and increasing the quality of the harvesting and transporting is necessary in order to reduce the damages to the fruit. Fruit acidity during storage after the impacts showed the significant changes that could negatively affect the taste of the fruit and as a result, its marketability.

Keywords:

Language:

Persian

Published:

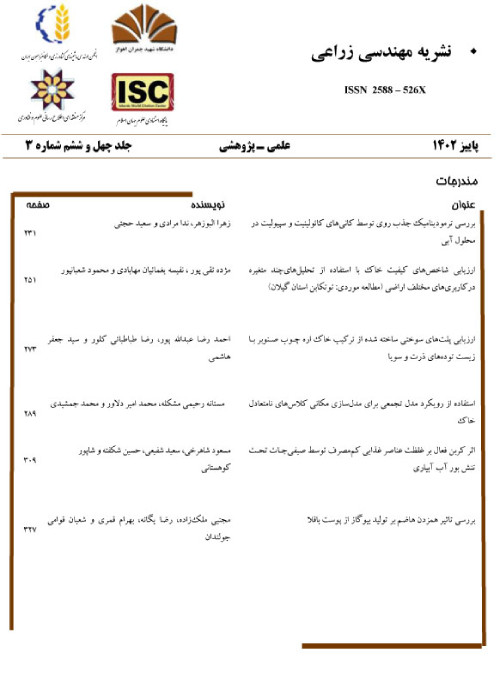

Journal of Agricultural Engineering, Volume:41 Issue: 3, 2018

Pages:

97 to 111

magiran.com/p1948992

دانلود و مطالعه متن این مقاله با یکی از روشهای زیر امکان پذیر است:

اشتراک شخصی

با عضویت و پرداخت آنلاین حق اشتراک یکساله به مبلغ 1,390,000ريال میتوانید 70 عنوان مطلب دانلود کنید!

اشتراک سازمانی

به کتابخانه دانشگاه یا محل کار خود پیشنهاد کنید تا اشتراک سازمانی این پایگاه را برای دسترسی نامحدود همه کاربران به متن مطالب تهیه نمایند!

توجه!

- حق عضویت دریافتی صرف حمایت از نشریات عضو و نگهداری، تکمیل و توسعه مگیران میشود.

- پرداخت حق اشتراک و دانلود مقالات اجازه بازنشر آن در سایر رسانههای چاپی و دیجیتال را به کاربر نمیدهد.

In order to view content subscription is required

Personal subscription

Subscribe magiran.com for 70 € euros via PayPal and download 70 articles during a year.

Organization subscription

Please contact us to subscribe your university or library for unlimited access!