Design, fabrication and testing of a new rototiller suitable for small farms and gardens

Author(s):

Article Type:

Research/Original Article (دارای رتبه معتبر)

Abstract:

Introduction Tillage is a main operation for seedbed preparation and is one of the major items of energy and cost expenditure in crop production. In the conventional rotary tillers, using the L-shape blades has numerous problems such as severe vibrational problems, weeds wrapping around the blades, and lower performance due to the limited power of such small tillers. Therefore in order to overcome the addressed problems, design, fabrication and evaluation of a new rototiller adapted for small farms and gardens were considered in this research.

Materials and Methods To start the design, the power requirement was estimated using a semi-theoretical model for the given working depth, working width, forward and rotational speed of the machine. Then a suitable engine was chosen based on the estimated power. The estimated power was 3.4 kW (4.5 hp); therefore, according to the available engines in the market for single cylinder gasoline engines, a Kato engine with 5.5 hp power and maximum speed of 3600 rpm was chosen. By reducing the rotational speed of the engine in three stages, rotational speed of the rotor was obtained in the range of 140-260 rpm. To transmit the power from the engine to the rotary axis, first, a pulley and belt mechanism (two V-shaped belt, type B) and then two chain mechanisms (roller chains 40 and 60) were used. Rotary axis with the diameter of 2.5 cm was made from steel E295. The fabricated rototiller has a working width of 60 cm, working depth of 7 cm, rotational speed between 140-260 rpm, forward speed equal to the operator’s translational speed, and maximum power equal to 5.5 hp.

The maximum force exerted on each of the blades was calculated equal to 84.10 kgf (824.73 N) using the theoretical approach proposed by Bernacki (1972). In the next step, numerical simulation of blades, flanges and rotating shaft for stress and strain analysis was performed using the Ansys software.

Farm experiments were carried out as split plots in citrus gardens based on randomized complete block design with three replications. The soil moisture content as the main plot varied in two levels (13.5-21.9 and 21.9-30.3 percent based on dry weight) and the rotational speed of blades as subplots varied in three levels (140-170, 170-200 and 200-230 rpm).

The measured parameters consisted of clod mean weight diameter, soil relent percentage, soil bulk density and specific fuel consumption. To determine the diameter of aggregates, a set of standard sieves with the diameter ranging from 0.5 to 8 mm were used. Then a laboratory shaker was used to sift the samples. Each sample was shaken for 30 sec. To determine the fuel consumption during the experiments, the filled fuel tank method was used. Data analyses including analysis of variance (Anova), mean comparisons and interaction between the parameters were performed using the SPSS 16 software.

Results and Discussion The numerical stress analysis of the flange showed that the maximum van - Mises stress occurred in the position of the blade-flange connections, with a magnitude of 52.98 MPa for the given working conditions, including soil engineering properties, working depth and other important parameters. The experimental results obtained in this study indicated that influence of soil moisture and rotational speed of blades on the clod mean weight diameter, soil relent percentage and specific fuel consumption were significant (P<0.01). The clod mean weight diameter was measured equal to 8 mm at high rotational speed (200-230 rpm) and high soil moisture content (21.9%-30.3%) and equal to 15 mm at low rotational speed (140-170 rpm) and low soil moisture content (13.5%- 21.9%). The maximum soil relent percentage was obtained equal to 97% at high rotational speed (200-230 rpm) and high soil moisture content (21.9%-30.3%).

Regarding the results obtained in this study, the specific fuel consumption increased first in a light slop, then in a steep rise with increasing the blades rotational speed. The reason can be the higher relent percent of the soil at higher rotational speeds and higher moisture contents, albeit at the examined range of 21.9-30.3. The specific fuel consumption was maximum at higher soil moisture content, i.e., 30 %. The results indicated that the blades rotational speed and soil moisture content had no significant effect on the field efficiency of the examined rototiller. Reduction of the rotational speed of the rototiller from high-to-moderate speeds yields decreasing the fuel consumption of 17 liter/ha, which could be significant in a wide scale soil tillage operations. As a general result, reduction of the rotational speed has some considerable advantages such as reducing the power requirements, reducing the blade wearing and maintaining the soil structure.

Conclusion The stress analysis of the fabricated machine together with the experimental and field measurements indicated that the new proposed and fabricated blades were a suitable choice for construction of small rototillers. The fabricated machine with the new blades showed some additional advantages including less specific energy consumption, less weeds wrapping around the blades, and less vibrational problems

Materials and Methods To start the design, the power requirement was estimated using a semi-theoretical model for the given working depth, working width, forward and rotational speed of the machine. Then a suitable engine was chosen based on the estimated power. The estimated power was 3.4 kW (4.5 hp); therefore, according to the available engines in the market for single cylinder gasoline engines, a Kato engine with 5.5 hp power and maximum speed of 3600 rpm was chosen. By reducing the rotational speed of the engine in three stages, rotational speed of the rotor was obtained in the range of 140-260 rpm. To transmit the power from the engine to the rotary axis, first, a pulley and belt mechanism (two V-shaped belt, type B) and then two chain mechanisms (roller chains 40 and 60) were used. Rotary axis with the diameter of 2.5 cm was made from steel E295. The fabricated rototiller has a working width of 60 cm, working depth of 7 cm, rotational speed between 140-260 rpm, forward speed equal to the operator’s translational speed, and maximum power equal to 5.5 hp.

The maximum force exerted on each of the blades was calculated equal to 84.10 kgf (824.73 N) using the theoretical approach proposed by Bernacki (1972). In the next step, numerical simulation of blades, flanges and rotating shaft for stress and strain analysis was performed using the Ansys software.

Farm experiments were carried out as split plots in citrus gardens based on randomized complete block design with three replications. The soil moisture content as the main plot varied in two levels (13.5-21.9 and 21.9-30.3 percent based on dry weight) and the rotational speed of blades as subplots varied in three levels (140-170, 170-200 and 200-230 rpm).

The measured parameters consisted of clod mean weight diameter, soil relent percentage, soil bulk density and specific fuel consumption. To determine the diameter of aggregates, a set of standard sieves with the diameter ranging from 0.5 to 8 mm were used. Then a laboratory shaker was used to sift the samples. Each sample was shaken for 30 sec. To determine the fuel consumption during the experiments, the filled fuel tank method was used. Data analyses including analysis of variance (Anova), mean comparisons and interaction between the parameters were performed using the SPSS 16 software.

Results and Discussion The numerical stress analysis of the flange showed that the maximum van - Mises stress occurred in the position of the blade-flange connections, with a magnitude of 52.98 MPa for the given working conditions, including soil engineering properties, working depth and other important parameters. The experimental results obtained in this study indicated that influence of soil moisture and rotational speed of blades on the clod mean weight diameter, soil relent percentage and specific fuel consumption were significant (P<0.01). The clod mean weight diameter was measured equal to 8 mm at high rotational speed (200-230 rpm) and high soil moisture content (21.9%-30.3%) and equal to 15 mm at low rotational speed (140-170 rpm) and low soil moisture content (13.5%- 21.9%). The maximum soil relent percentage was obtained equal to 97% at high rotational speed (200-230 rpm) and high soil moisture content (21.9%-30.3%).

Regarding the results obtained in this study, the specific fuel consumption increased first in a light slop, then in a steep rise with increasing the blades rotational speed. The reason can be the higher relent percent of the soil at higher rotational speeds and higher moisture contents, albeit at the examined range of 21.9-30.3. The specific fuel consumption was maximum at higher soil moisture content, i.e., 30 %. The results indicated that the blades rotational speed and soil moisture content had no significant effect on the field efficiency of the examined rototiller. Reduction of the rotational speed of the rototiller from high-to-moderate speeds yields decreasing the fuel consumption of 17 liter/ha, which could be significant in a wide scale soil tillage operations. As a general result, reduction of the rotational speed has some considerable advantages such as reducing the power requirements, reducing the blade wearing and maintaining the soil structure.

Conclusion The stress analysis of the fabricated machine together with the experimental and field measurements indicated that the new proposed and fabricated blades were a suitable choice for construction of small rototillers. The fabricated machine with the new blades showed some additional advantages including less specific energy consumption, less weeds wrapping around the blades, and less vibrational problems

Keywords:

Language:

Persian

Published:

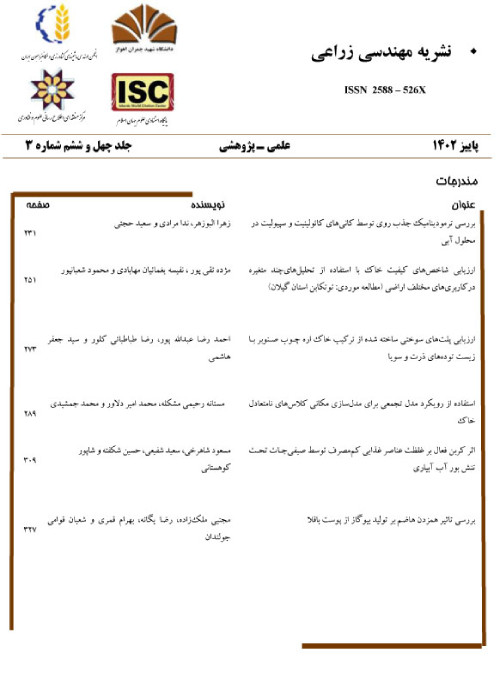

Journal of Agricultural Engineering, Volume:41 Issue: 1, 2018

Pages:

29 to 44

magiran.com/p1901249

دانلود و مطالعه متن این مقاله با یکی از روشهای زیر امکان پذیر است:

اشتراک شخصی

با عضویت و پرداخت آنلاین حق اشتراک یکساله به مبلغ 1,390,000ريال میتوانید 70 عنوان مطلب دانلود کنید!

اشتراک سازمانی

به کتابخانه دانشگاه یا محل کار خود پیشنهاد کنید تا اشتراک سازمانی این پایگاه را برای دسترسی نامحدود همه کاربران به متن مطالب تهیه نمایند!

توجه!

- حق عضویت دریافتی صرف حمایت از نشریات عضو و نگهداری، تکمیل و توسعه مگیران میشود.

- پرداخت حق اشتراک و دانلود مقالات اجازه بازنشر آن در سایر رسانههای چاپی و دیجیتال را به کاربر نمیدهد.

دسترسی سراسری کاربران دانشگاه پیام نور!

اعضای هیئت علمی و دانشجویان دانشگاه پیام نور در سراسر کشور، در صورت ثبت نام با ایمیل دانشگاهی، تا پایان فروردین ماه 1403 به مقالات سایت دسترسی خواهند داشت!

In order to view content subscription is required

Personal subscription

Subscribe magiran.com for 70 € euros via PayPal and download 70 articles during a year.

Organization subscription

Please contact us to subscribe your university or library for unlimited access!