The investigation and evaluation of three types of wheat cleaning systems in Hamedan

Author(s):

Article Type:

Research/Original Article (دارای رتبه معتبر)

Abstract:

Introduction

The cleaning operation is an important process to increase the seeds’ purity degree. Cleaning is the most fundamental task in a cleaning machine, which separates the impurities of the healthy seeds. In a research that was conducted by Chenari et al. (2013), The efficiency of three types of wheat cleaning machines, R-Machine, Cimbria, and Gold-Saat, was investigated. The results of the statistical analysis showed the Cimbia machine had the greatest cleaning efficiency (86.72%). The R-Machine and Gold-Saat had 80.64% and 81.59% total efficiency, respectively. In this study, the effects of three different cleaning machines were evaluated on the seed losses percentage and seed cleaning percentage of all outputs in various pre-cleaning and cleaning machines for cleaning wheat seeds.

Materials and Methods

In this study, three types of various cleaning systems were investigated to study their performances on wheat cleaning rate in Hamedan Province. Generally, a cleaning system is constructed of 5 parts: (1) pre-cleaning machine, (2) cleaning machine, (3) Trieurs, (4) weighting system, (5). packaging system. In this study, the term cleaning system refers to only the first and the second part of the cleaning system. The cleaning systems in the study were (Table 1): (1) R-Machine with pre-cleaning machine model ARS2000, made in Iran, (2) Ram-Sanat with pre-cleaning machine model RAM200, made in Iran, and (3) Gold-Saat with pre-cleaning machine model GS100S, made in Germany. Table 1 shows the characteristics of three different cleaning systems, containing cleaning and pre-cleaning machines. Fig. 1 shows a schematic of the inputs and outputs of the wheat cleaning system (containing pre-cleaning and cleaning machines with Trieurs). Some factors were considered and determined as the following: (1) theoretical and practical capacity in ton/ha: based on the factory’s manual, the theoretical capacity for pre-cleaning machine and cleaning machine were 20 and 5 tons/ha, respectively; whereas, the practical capacity was calculated 2.2 tons/ha for total system (pre-cleaning machine and cleaning machine); (2) purity percentage of wheat input: this factor was determined for the pre-cleaning machine as follows: purity percentage of healthy seeds input = (weight of healthy seeds / total weight) × 100; (3) loss percentage of all outputs in the pre-cleaning machine, loss percentage of all outputs in the cleaning machine, and the total loss percentage of the system, as below: Loss percentage of each of output on the cleaning system = (weight of lost seeds / total weight) × 100. A completely randomized design was used in the research and Duncan’s test was used to compare the means results.

Results and Discussion

Table 2 shows the means of different parts of cleaning systems (containing pre-cleaning and cleaning machines) by Duncan’s method. Thus:

Pre-Cleaning Machine

Wheat input impurity or purity percentage: Table 2 indicates non-significant differences between wheat input impurity and purity percentage as affected by various wheat input to the cleaning system. Loss percentage in the second suction of the pre-cleaning machine: Table 2 indicates significant differences between loss percentage in the second suction of the pre-cleaning machine. The maximum loss percentage belonged to Ram-Sanat, and the Gold-Saat had the minimum amount.

Cleaning Machine

Loss percentage in suction: the result shows significant differences between loss percentage in primary and final suction of the cleaning system. Loss percentage in sieves of the cleaning machine: Table 2 indicates significant differences between loss percentage in the top of the upper sieve and below th downer sieve of the cleaning machine. Loss percentage in barely cleaning and semi-wheat cleaning parts: based on Table 2, a significant difference between them is observed. The maximum losses belonged to Ram-Sanat, and the R-Machine had the minimum amount.

Cleaning System (Pre-Cleaning and Cleaning Machine Combination)

Purity percentage of wheat output (last purity): the results of the analysis of the variance show that all cleaning machines have the seed final purity percentage greater than 98%. Total loss percentage of the system: the results show that the total loss percentage of Gold-Saat, R-Machine and Ram-Sanat are 6.04%, 2.97% and 4.4%, respectively. Also, the results show that seed loss is zero for meshed cylinder, but the wheat loss of pre-cleaning and cleaning machines for all outlets is significant (p < 1%). These results are in agreement with Safarzadeh, (1993) and Jilanchi et al., (1997).

Conclusion

The results show that all three cleaning machines have the final purity seed percentage greater than 98%, and also the minimum wheat loss (3.0%) belonged to Ram-Sanat cleaning machine. The R-Machine and Gold-Saat had 4.4% and 6.0% total loss.Keywords:

Language:

Persian

Published:

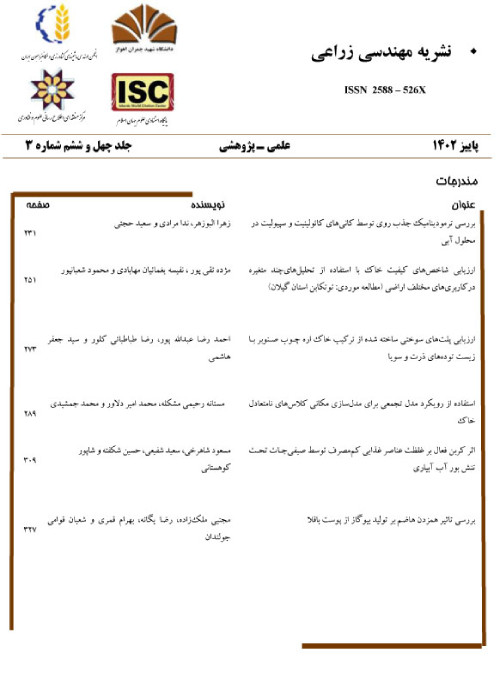

Journal of Agricultural Engineering, Volume:42 Issue: 1, 2019

Pages:

33 to 46

magiran.com/p2004200

دانلود و مطالعه متن این مقاله با یکی از روشهای زیر امکان پذیر است:

اشتراک شخصی

با عضویت و پرداخت آنلاین حق اشتراک یکساله به مبلغ 1,390,000ريال میتوانید 70 عنوان مطلب دانلود کنید!

اشتراک سازمانی

به کتابخانه دانشگاه یا محل کار خود پیشنهاد کنید تا اشتراک سازمانی این پایگاه را برای دسترسی نامحدود همه کاربران به متن مطالب تهیه نمایند!

توجه!

- حق عضویت دریافتی صرف حمایت از نشریات عضو و نگهداری، تکمیل و توسعه مگیران میشود.

- پرداخت حق اشتراک و دانلود مقالات اجازه بازنشر آن در سایر رسانههای چاپی و دیجیتال را به کاربر نمیدهد.

دسترسی سراسری کاربران دانشگاه پیام نور!

اعضای هیئت علمی و دانشجویان دانشگاه پیام نور در سراسر کشور، در صورت ثبت نام با ایمیل دانشگاهی، تا پایان فروردین ماه 1403 به مقالات سایت دسترسی خواهند داشت!

In order to view content subscription is required

Personal subscription

Subscribe magiran.com for 70 € euros via PayPal and download 70 articles during a year.

Organization subscription

Please contact us to subscribe your university or library for unlimited access!