فهرست مطالب

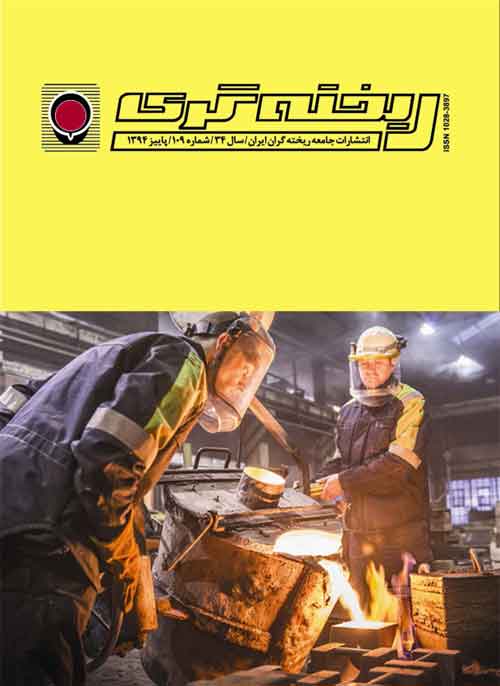

نشریه ریخته گری

پیاپی 109 (پاییز 1394)

- تاریخ انتشار: 1394/09/30

- تعداد عناوین: 8

-

-

بررسی کارایی آمیژان Al-5Ti-1B بر ویژگی های ریزساختاری و مکانیکی آلیاژ Al-6%Mg پس از روزنرانیصفحه 2

-

بررسی تاثیر ترکیبات بین فلزی غنی از آهن بر استعداد به پارگی گرم آلیاژهای هیپویوتکتیک Al-Siصفحه 13

-

تکنولوژی ریخته گری و عملیات حرارتی قطعات چدنی نیکل سختصفحه 23

-

بررسی تاثیر دمای فوق گداز بر مقاومت به سایش فولاد منگنزدار هدفیلدصفحه 32

-

نسل جدیدی از مواد دما بالا بر پایه ترکیب بین فلزی Ni3Alصفحه 40

-

شبیه سازی تشکیل جریان گردابی حین تخلیه مخازن متالورژیکیصفحه 50

-

بررسی علت شکست قطعه یوغ فرمانصفحه 61

-

تاثیر ذرات کاربید سیلیسیوم بر روی مقاومت به سایش کامپوزیت سولفات باریم، پودر مس و پودر روی برای کاربرد مواد اصطکاکیصفحه 71

-

Investigation of Al-5Ti-1B master alloy on microstructure and mechanical properties of Al-6%Mg after extrusion processPage 2

Since the grain refining process of aluminum alloys have a large impact on the quality of alloy part, the current study has been devoted to investigate the effect of titanium on the microstructure and tensile properties of Al-6%Mg alloy after extrusion process. Therefore titanium was added to molten Al-6%Mg alloy by using Al-5Ti-1B master alloy at various content (0.01, 0.03, 0.05, 0.1, 0.2, 0.3% weight percent), and the samples was extruded with a ratio of 6:1. It was found that refined specimens have more homogenous microstructure and finer grains in comparison with unrefined specimen, the morphology of columnar alpha dendrites also turn into rosette like. In alloy which refined with titanium, the volume fraction of intermetallic products reached to the lowest level in the homogenization temperature of 500 °C. Extrusion process caused recrystallized grains at 500 °C. Tensile test results also showed that the grain refining process changes the tensile properties and reflects the positive impact on the tensile properties which obtained from hot extruded process.

-

An investigation on the effect of Fe-rich intermetallics on hot tearing susceptibility in hypoeutectic Al-Si alloysPage 13The effect of iron (0.2 to 2 wt%) on the hot tearing susceptibility of Al-5Si and Al-9Si alloys was investigated. According to the results, addition of iron up to the 2 wt% improved hot tearing resistance of Al-5Si alloy and decreased its HTS by about 100%. This improvement was assumed to be mainly due to the fine and interdendritic distribution of Fe-rich intermetallic compounds. In the case of Al-9Si alloy however, despite of the lower solidification range and higher fluidity, addition of iron up to 2 wt% deteriorate hot tearing resistance. The HTS index was increased continuously by three times. Microscopic examination of the hot tear cracks reveals the precipitation of higher amounts of -Al5FeSi in interdendritic regions which adversely affect the tensile strength and elongation as well as blockage the interdendritic feeding channels thereby decrease the hot tearing resistance.Keywords: Hypoeutectic, Al-Si, hot tearing, intermetallic, Iron

-

Production Technology and Heat Treatment of Ni-Hard Cast IronsPage 23Extraction of Mineral Materials From Various Mines, and Grinding the ores , are depending on quality production of abrasion resistant cast Irons, Ni-Hard cast irons, which have good toughness and abrasion resistant and hardness properties, are important family in this case. Chemical composition microstructure and phase transformation in these alloy have considerable effects on casting properties. This manuscript consider production process of Ni-Hard cast irons.Keywords: Ni-Hard Cast Irons, Abrasion Resistance Cast Iron, Melting, Casting of Cast Irons, White Alloys Cast Irons

-

Investigation on Effect of Melt Super-Heating Temperature on the Resistance to Abrasion of Hadfield Manganese SteelPage 32In this study, the effects of melt super-heating on the resistance to abrasion of Hadfield manganese steel have been investigated. For this purpose, initially four disc-shaped aluminum models prepared and then molding accomplished through Sodium Silicate/CO2 and silica sand procedure as closed feeding method. Coreless induction furnace was used to melt preparation. Super-heating temperatures 1350, 1400, 1450 and 1500°C considered when pouring in molds. After the casting, every four casted blocks were quenched into the pure water bath. Optical microscopy method was used to evaluate the microstructure of samples, pin on disk method applied to evaluate the abrasion resistance and scanning electron microscopy method was used for evaluation of the wear surfaces and wear mechanism of them. Optical microscopy observations showed that the super-heating temperature increase, leads to decreasing carbide precipitates and increases austenite grains size in the Hadfield steel microstructure. Wear test results shows that the super-heat temperature increase leads to increasing resistance to abrasion in the Hadfield steel. According to the research results, the best wear resistance observed in the piece casted with 1500°C super-heat temperature.Keywords: Hadfield steel, melt super-heating, resistance to abrasion, microstructure

-

A new generation of high-temperature materials based on Ni3Al intermetallic compoundsPage 40The nickel aluminide Ni3Al has a Ll2 (cP4) crystal structure and remains ordered up to its melting point (~1395◦C). Ni3Al (γ′) serves as the strengthening constituent in many commercial nickelbased superalloys and in this use exhibits excellent high temperature strength and creep resistance. Unalloyed Ni3Al has negligible tensile ductility at room temperature and fails by brittle, intergranular fracture, mainly because of moisture-induced hydrogen embrittlement. The current generation of hypostoichiometric Ni3Al alloys doped with boron (Keywords: intermetallic compounds, nickel aluminide, Ni3Al

-

Numerical simulation of vortex formation during discharge of metallurgical vesselsPage 50Metallurgical vessels, such as tundishes in the continuous casting process, are widely used in metal casting industries. The formation of vortical flow is very common during the discharge of these vessels. As a consequence a spiral is commonly forms at the later stages of vessel discharge. It can enter floating slags into the melt that significantly decreases the metallurgical quality of molten metal. Furthermore, when the height of melt is less than a critical value, an air core is formed at the center of vortex. It leads to the suction of a large amount of air into the molten metal that leads to the air entrapment in the melt and its severe oxidation. The formation of such a vortical flow is studied by means of numerical simulation in the present study. The effect of existing initial tangential velocity (radial flow), holding time of stopper rod, slope of vessel walls and the diameter of inner wall in the outlet are studied systematically. According to our results, the existence of radial component in the velocity field is the most important factor that contributes in the formation of spiral flow. Moreover, the existence of negative slope in the vessel can decrease the susceptibility of spiral flow formation.Keywords: tundish, defect entrainment, discharge flow, spiral flow simulation, vortex

-

An Investigation To the Failure Reasons OF the Steering yokePage 61In view of the high rate of components failure in the automotive industry, being familiar with the failure analysis methods and the ineffectiveness of these components is essential.

Steering yoke is one of the most sensitive components in the automobile. Connections occurred in this component must have sufficient strength for passenger safety.

In this research, the failure of a typical yoke was investigated metallurgically after the impact test. The results showed that the presence of massive nitride impurities in the HAZ region and also, the presence of B and Ti elements and their effect on hardenability are the main causes of such failures.Keywords: yoke-nitride inclusions-friction welding-failure -

Effect of silicon carbide particulates on wear resistance of composite barium sulfate, copper powder, Zinc powder, for friction materials application.Page 71In this study, the weight percent of the composite non-asbestos brake bad wear SiC properties were studied for this purpose a sample with 5wt%, 10,15 and 20 and a sample was made without SiC. Abrasion test was conducted and it was found G99-95a standard sample with 15 wt% of SiC has good resistance to craking and abrasion as well as restore power to the right and the coefficient of friction is desirable.Keywords: Brake Pad, SiC, Wear properties, Fraction, Power Recovery, Friction coefficient